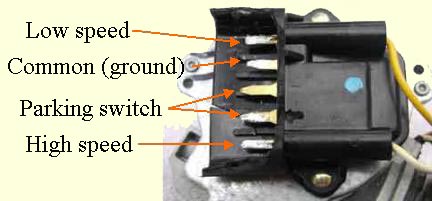

The Saturn wiper motor has a block with 5 electrical terminals. One terminal goes to ground (Common), one is for high speed, one low speed and two for a parking switch. It's important to note that the Common terminal is connected to the motor casing. This could be a factor if you mount the motor to a metal chassis or have other exposed wires in the vicinity of the motor.

The parking switch is used to bring the wiper blades to their "parked" position when used on a car. During motor operation, the two terminals are connected to each other about 90% of each rotation. They open during the other 10%. I haven't used this function, but it could be used to "flash" a light or possibly in conjunction with a microcontroller to count revolutions and make something happen every Nth revolution.

|

I cut away the plastic casing over the terminals so I can solder wires to them. The table below gives hookup information for the Saturn motor.

|

|

|

This

type of crimp-on connector in the 3/16" width works well without

soldering.

|